What is Eddy Current Testing?

Eddy Current Frequently Asked Questions

Eddy Current Testing is a form of non-destructive testing used in industries like nuclear power, conventional power plants, petroleum refineries, and petrochemical facilities. Eddy Current Testing is used on materials such as titanium, aluminum, stainless steel, conductive materials, copper alloys in your machinery, and pipping. It helps detect and track flaws for overall better maintenance.

But what is Eddy Current Testing and is it something my plant needs to invest in? Does it really have benefits when it comes to titanium tubes, heat exchangers, and overall plant performance? The answer is yes!

As the leading efficiency experts, American Efficiency Services has answered your most popular questions when it comes to Eddy Current Testing and we break down the why, the when, and the who.

Table of Contents

How Does Eddy Current Testing Work?

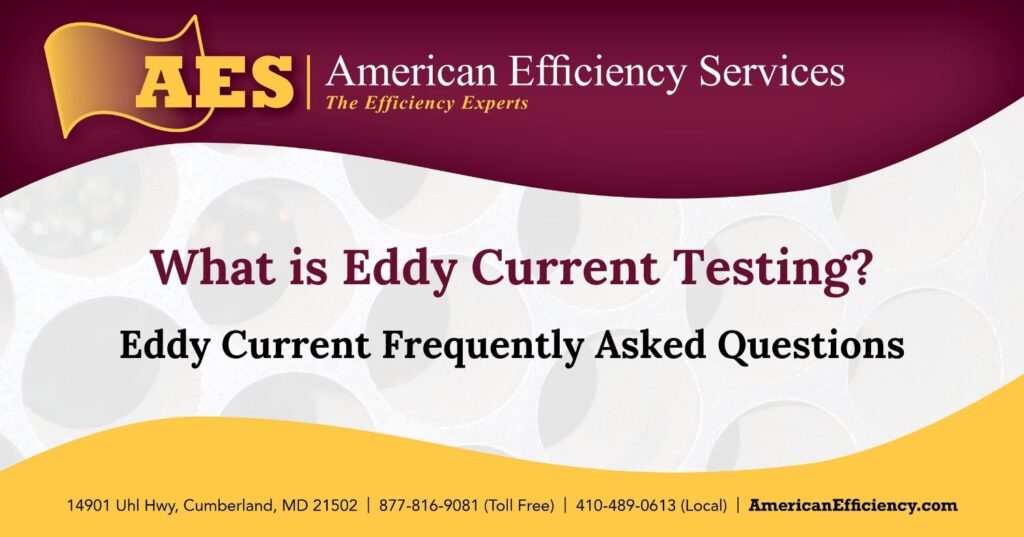

The most basic form of the Eddy Current Testing principle uses a single coil that is excited using alternating electrical currents. When the wire is excited, it produces an electromagnetic field around the coil. The electromagnetic field oscillates at the same frequency that runs through the coil. Introducing the coil to conductive material will create currents that are opposed to the ones in the coil, and these currents are Eddy Currents.

A fault or break stops the Eddy Current’s oscillation, and the voltage will spike back to the original levels before the Eddy Currents were introduced. The conductive material will not upset or change the spinning of Eddy Currents, but faults, cracks, and corrosion will. When the voltage jumps, it typically means there is a fault in the material being tested.

Eddy Current Testing in Your Facility

How Often Should I Eddy Current My Tubes?

- Every time you have an event that compromises your tubes

- Every outage or every other outage, depending on the condition and/or age of your tubes trending their wear (help prevent tube leaks resulting from compromised tubes during peak operating periods)

- Within the first year of the component being placed into service to establish a baseline for future trending

Why do I Need to do Eddy Current Testing on my Titanium Tubes?

They Should Last Forever!

Many clients don’t realize the importance of performing eddy current testing on their titanium tubes. While titanium tubes are resistant to chlorides and corrosion, they are still susceptible to tube wear and erosion. The misplaced confidence in titanium tube performance makes heat exchanger owners skip preventative testing.

The Dangers

By the time there is a tube failure in titanium tubes, there is a higher cost associated with understanding and/or correcting the problem due to having to come down in power to plug tubes. There is also a higher percentage of tubes needing inspection to identify the cause of failure.

Prevention

Performing regularly scheduled Eddy Current testing will save you money in the long term by avoiding unexpected shutdowns or malfunctions and can help crews more easily find sources of wear and tear versus efforts to correct the problem after a failure.

Does Eddy Current Testing Affect My Heat Exchanger Health?

Eddy Current Testing plays a vital role in the life cycle management of heat exchangers for the power generation marketplace. Periodic inspection of these components with eddy current testing is necessary to maintain and extend the efficient operability of nuclear, fossil power plants, and any industrial facility that has tube heat exchangers as part of their systems.

The Benefits

Knowing the health of your heat exchangers will put you in a stronger position to plan for the future. Avoid costly maintenance or repairs down the line and better understand the efficiency operations of your plant.

How Often Should I Perform Eddy Current Testing on My Heat Exchangers?

Eddy current testing should be performed during every outage or if there was an event that could have affected a component’s tubes. If you are unsure about your eddy current testing schedule for your heat exchangers, give American Efficiency Services a call and we would be happy to help consult and plan for your next outage.

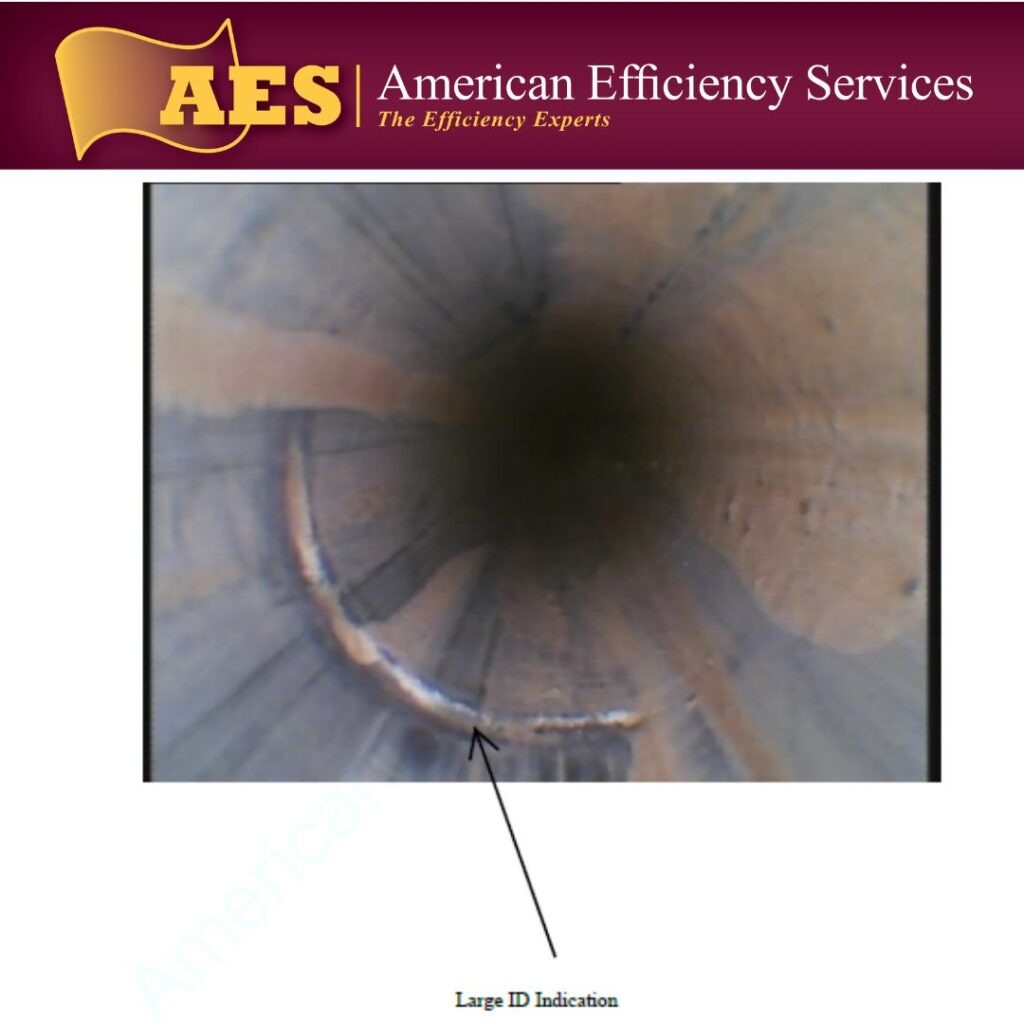

Eddy Current In Action

Job Highlight from AES

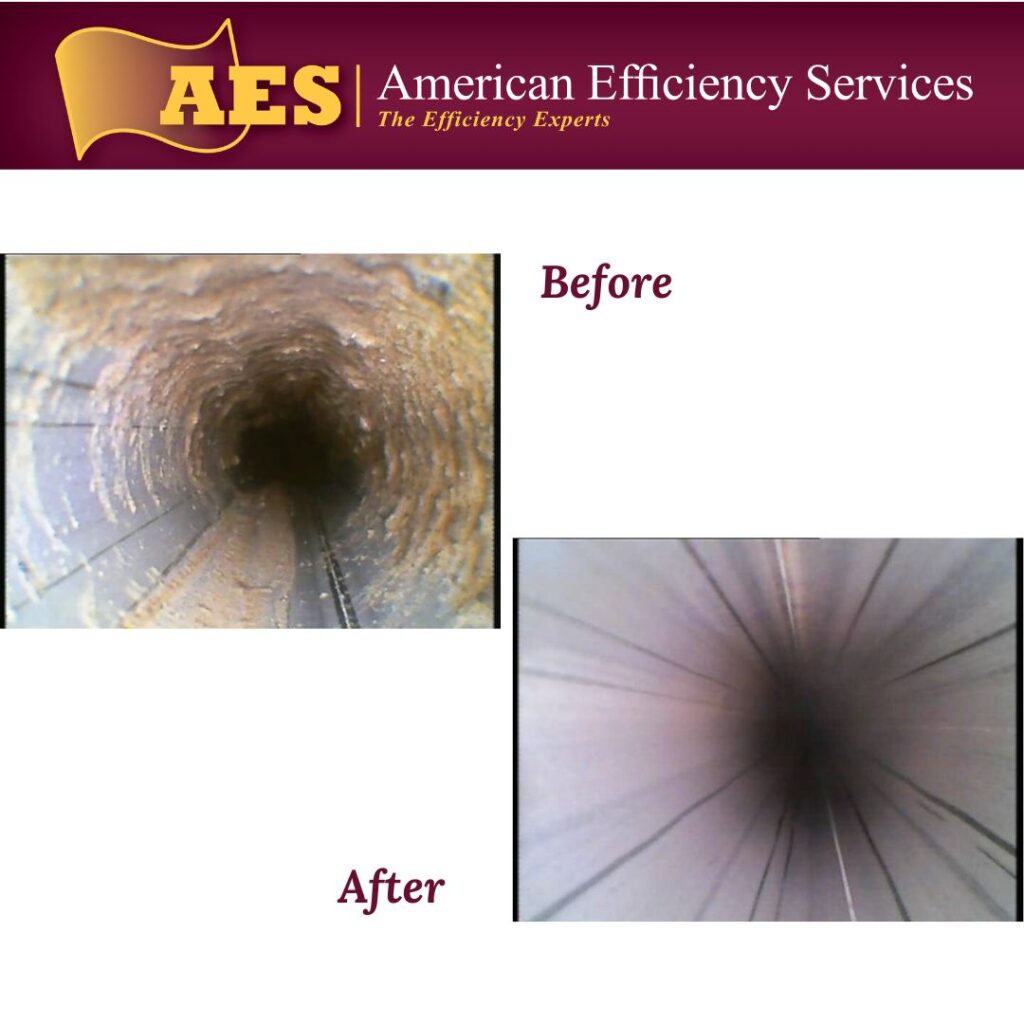

American Efficiency Services completed a 100% Eddy Current inspection and cleaning on a condenser in Oklahoma. The customer wanted the inspection spaced out over four outages, so our team cleaned and tested a separate tube bundle quadrant each time.

Staying in this rotation over the next four outages provided the information needed to determine trends for wall loss, pitting, and vibration damage, as well as keeping the tubes clean for proper heat transfer.

Job: Success

Before + After Results

Do You Need More Than Eddy Current Testing?

American Efficiency Services is proud to offer bundled services to help you with everything your site needs – we bundle services, cross-train our employees, and have crews available 24/7 for emergencies. Eddy Current Testing is only the beginning – get comprehensive maintenance services for the best efficiency possible.

- One Vendor, Multiple Services

Less downtime, reduced safety hazards, clear communication from start to finish. - Safety First

Continued safety briefings, a focus on safety communication, OSHA training, and more - Tube Cleanings

Maintain your tubes for the best efficiency and reduce spikes in cost - Products Available

Ask about cradle-lock tube stakes, s-flex designs, basket tips, and more

American Efficiency Services

American Efficiency Services was founded in 2001 to provide quality, satisfaction-guaranteed helium leak detection services to the power generation marketplace. AES has grown in sales, staff, and scope each year since its founding and now has offices in Maryland, Missouri, Florida, and Texas to serve customers across the nation – and the world – 24 hours a day/7 days a week.

- American Efficiency Services