American Efficiency Services

Safely Providing Services & Products to Optimize Operational Efficiency

Serving the Power Generation, Process, & Industrial Markets

Safely Providing Services & Products to Optimize Operational Efficiency

Serving the Power Generation, Process, & Industrial Markets

We Have Six Offices Across America

Cumberland, Maryland (HQ)

Morganton, North Carolina

Tampa, Florida

Norfolk, Virginia

St. Louis, Missouri

Arlington, Texas

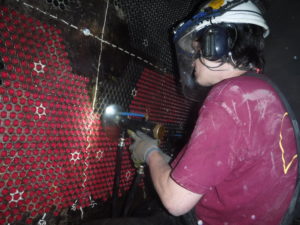

Our Featured Tube Cleaning Services

Since 2001, AES has provided open, clear communication and valuable system information to our customers for leak detection services and tube cleaning, which has now evolved into include expansion joint repair and replacement, eddy current testing, vibration resolution, and retubing. Our reporting system transfers photographs, diagrams and video images directly from the work area. Our findings are detailed in comprehensive final reports providing the information, including charts, analysis, and recommendations, you need to determine potential patterns of failure for maintenance and to aid plant personnel in prioritizing and making repairs. In fact, our final reports are so thorough and contain so much valuable information, a plant manager remarked that they were “almost too good”.

Leave nothing to chance when you hire AES—we get the job done and ensure you know what we know every step of the way. We are the Efficiency Experts.

AES employs the most educated and experienced staff of inspectors in the industry. While no inspection or scenario is ever the same, our experience level combined with our employees’ vast knowledge base, means we will locate all leaks while on-site; in fact, we guarantee it.

Trust AES for your helium inspection needs and see why we are the Efficiency Experts.

Learn More About Condenser Air-In Leakage Testing

Included as part of our expansion joint replacement and repair project management services, AES:

- documents all “as found” expansion joint conditions, both internally and externally;

- cleans all surface areas to prep for installation;

- inspects all studs, clamping bars, and steam shields;

- reports any replacement parts or repairs that are necessary to plant management early in the process.

Trust AES for your expansion joint needs and see why we are the Efficiency Experts.

AES will now be the sole source provider of the patented S-Flex® steam inlet expansion joint and S-Flex II® system, including the capability to provide turnkey installation solutions.

Trust AES for superior expansion joint products and see why we are the Efficiency Experts.”

When coupled with our tube cleaning program, these services can reduce the cost of both cleaning and eddy current inspection. Routine cleanings assist with immediate improvements to heat transfer and allow for quality eddy current data to be collected.

Trust AES for your eddy current testing and see why we are the Efficiency Experts.

Whether you are a new client or coming back for repeat services, we have a strategy in place to tackle your tube cleaning. Working closely with Goodway, we offer a variety of cleaners and chemicals for the various fouling mechanisms identified inside of condenser tubes. We will create a cleaning project plan to help keep your tubes clean and improve your plant’s performance.

Trust AES for your tube cleaning services and see why we are the Efficiency Experts.

Using our proven sequenced approach, AES ensures that complex projects are performed safely and delivered with quality workmanship, on time, and within budget.

We provide top-notch condenser retubing tasks including:

- Sample Tube Removal

- Tube/Tube Sheet Plugging

- Tube Sleeving

- Tube Procurement

- Tube Sheet Replacement

- Tube Sheet Serrating

- Tube Expansion

- Tube Staking

Trust AES for your condenser retubing services and see why we are the Efficiency Experts.

Tube vibration, if left unresolved, may result in catastrophic tube failures and the subsequent unplanned shutdown of the unit. All AES Cradle-Lock® stakes are custom-engineered and fabricated of 304 stainless- steel using precision dies to precisely mimic the tube pitch and spacing characteristics of your condenser or heat exchanger. No matter you design, tube spacing, or tube material we have a Cradle-Lock® stake design that will protect your tubes from damage as a result of vibration.

Trust AES to solve your tube vibration challenges and see why we are the Efficiency Experts.

Trust AES for all your condenser maintenance, testing, and repair services and see why we are the Efficiency Experts.

Where to Find Us in 2026

Conferences and Expositions

- January 20-22: PowerGen - San Antonio, TX

- January 27-29: EPIC Energy - Bismark, ND

- February 2-6: EPRI Heat Rate - Charlotte, NC

- More To Be Announced

Safety Comes First

Why Choose American Efficiency Services for Your Industrial Needs?

American Efficiency Services is the industry leader in providing a full line of product and service offerings to keep your unit running efficiently. Using our proven and safe technologies, our services and products are offered throughout the United States and abroad at electrical generating, petrochemical, paper, food processing, pharmaceutical, and ethanol-producing facilities.

Let AES be your trusted source for safely providing a full range of superior products and services including: helium leak detection, electrical generator and condenser tube inspections, condenser tube cleaning, eddy current inspections, condenser expansion joint replacement, S-Flex® and S-Flex II® steam inlet expansion joints and system, turn-key condenser retubing projects, vibration resolution utilizing our Cradle-Lock® anti-vibration stakes, and basket tips drilled to ASME standards.

We are the only company that stands behind our leak detection service with this guarantee – if we don’t find the leak, you don’t pay. AES is your trusted, expert source for safe, superior services.

In short, AES is your one-stop shop for the industry!

Headquartered in Maryland, AES is supported by six fully staffed offices in Florida, Missouri, North Carolina, Texas, and Virginia. With so many locations, we service the entire United States and can also travel to support our international customers–all on time and cost-effectively.

Contact us today to discuss how our services and products can work for you. Our crews are available 24/7 and staffed with personnel who are committed to uphold the highest degree of safety, professionalism, and industry standards. Call us and discover the American Efficiency Services way.