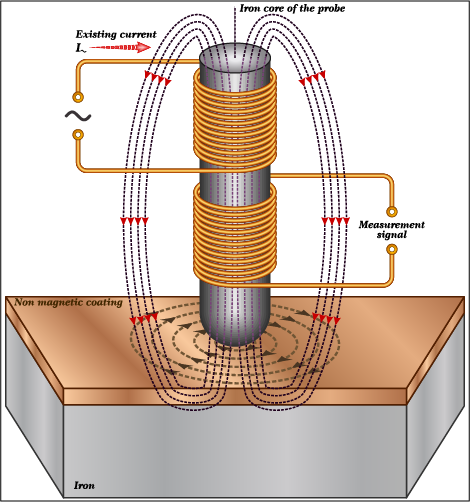

Most people are not familiar with Eddy Current or Eddy Current Testing but ECT has become a star in the field of non-destructive testing. Eddy Current Testing is the use of electromagnetic testing to find leaks and identify surface and sub-surface flaws in conductive materials. It is also used to examine non-ferrous tubing in condensers and heat exchangers.

Eddy-current testing is great for checking the pipe’s surface area, checking for faults inside pipes, remote testing of carbon steel pipes, eddy current weld inspection, and clad thickness. Outside of our industry, the most common use of Eddy Current is in metal detectors. Eddy Current Flaw Detector is very good for inspecting metallic parts.