7 Ways AES Improves Your Cost Savings with Efficient Plant Maintenance

Why Safety and Efficiency Saves You Money: Serving Power Generation, Process, and Industrial Markets

We haven’t met an owner or manager yet who wasn’t concerned with their cost of operations. Power plants, nuclear plants, chemical manufacturing, manufacturing plants, and more all have a high cost of operation with a need for reliability. Downtime is often not an option.

American Efficiency Services has continued to serve the power generation and industrial market with experienced, expert crews who can tackle the maintenance and repairs of heat exchangers, tube cleanings, air inleakge, leak detection, helium inspections, and more.

Discover how one efficient team that puts safety first can be the key to saving you money and reducing your downtime.

Why AES

AES offers all of the services you need under one contracted crew. We provide bundled services and cost discounts. So you can get Eddy Current Testing, leak detection, and more from one crew to improve the efficiency of your operations.

- Reduce downtime

- Peace of mind with safety-first approach

- Experienced professionals

- Expert solutions

- Thorough communication

- Detailed reporting

Table of Contents

Cost Savings with AES Efficiency Experts

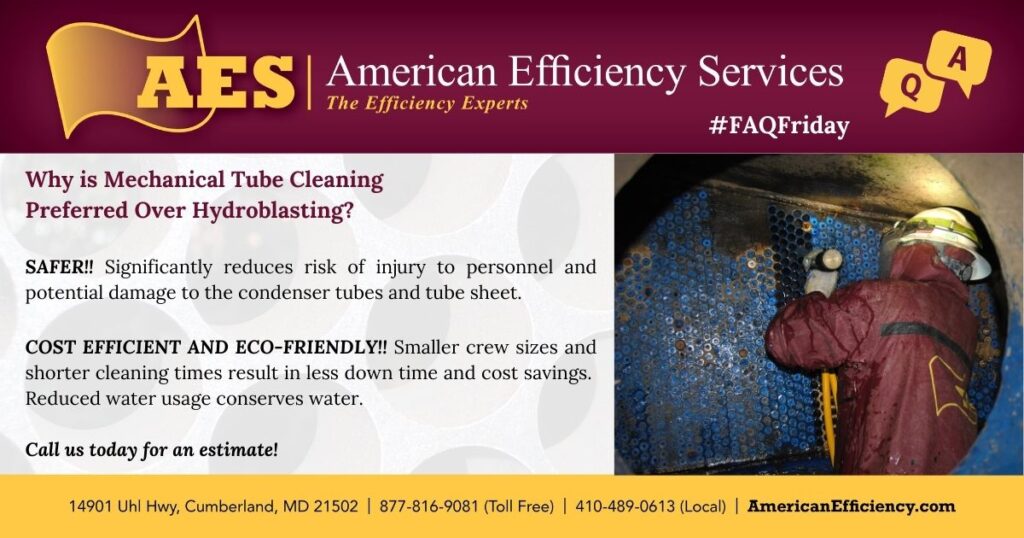

No More Dirty Tubes Affecting Condenser Performance

When you have dirty tubes, you are losing money and efficiency. Dirty tubes reduce the heat transfer, which lessens efficient cooling. This results in increased back pressure, which lowers the condenser performance. You’ll end up spending more due to lowered efficiency, watching your costs go up over time, sometimes year after year.

Don’t let dirty tubes be the reason your condenser has a poor performance. With our tube cleaning services, you can see a dramatic change in improvement.

Reducing the Costs of Air Inleakge

How much do you think air inleakage is costing you? Would you believe us if we told you it could be a difference of $616,500?

The average annual cost for one 400 MW unit operating with a 0.5″ Hg of backpressure deviation without identifying and repairing leaks can be $625,000. Yet the average annual inspection cost from AES is only $8,500.

Annual leak detection can dramatically improve the efficiency of your equipment, reducing downtime and lowering costs. We make inspections easy, so you can save money and stop worrying about downtime.

Helium Leak Detection Guarantee

AES never stops improving, whether it’s addressing tube leaks, safety, communication, or team building. All of this comes together to say goodbye to the method of finding a tube leak with shaving cream and luck from the 20th century, and instead, upgrading to helium leak detection and giving you a guarantee.

Helium leak detection technology allows us to quickly locate condenser tube leaks. This allows us to eliminate condensate contamination and improve performance to get your plant operating back to full power.

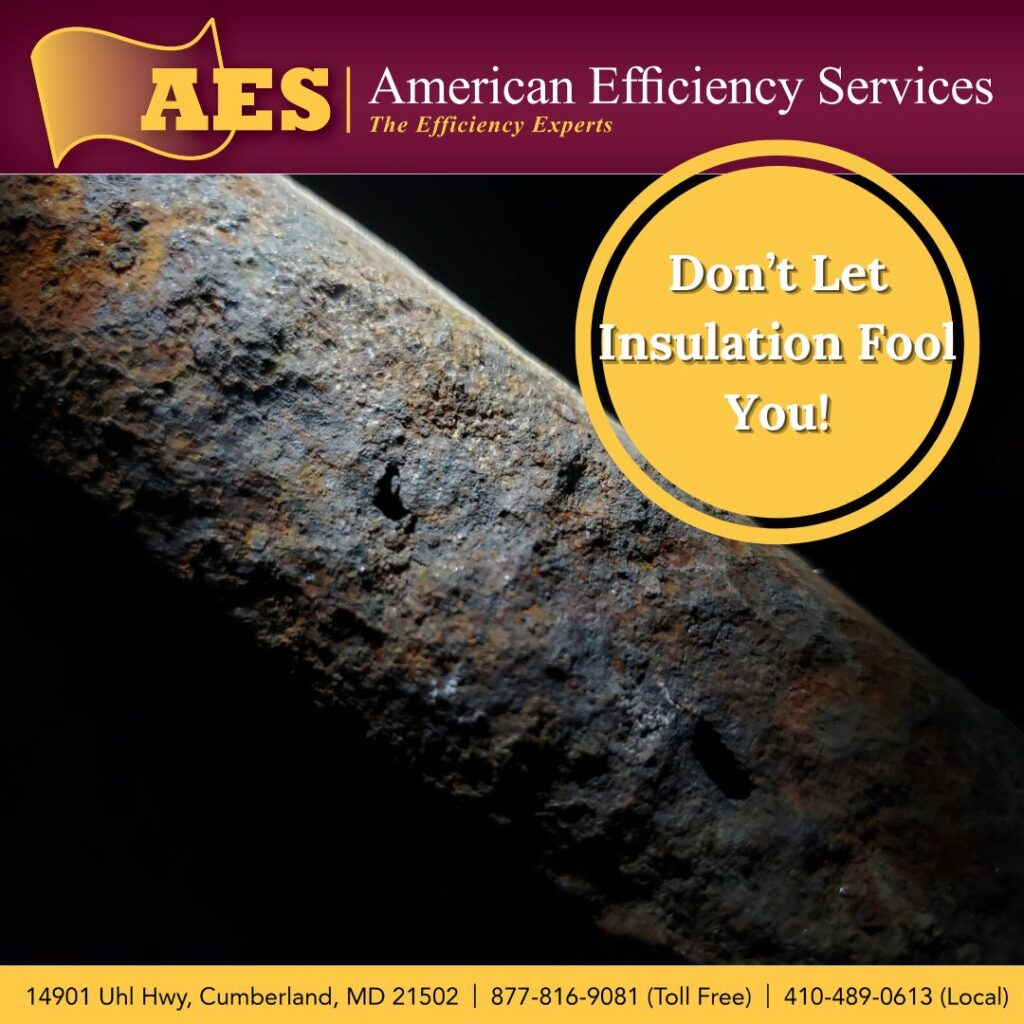

Peek Behind the Insulation

You may not want to look behind the insulation, but for our crew, it’s the only way to confirm our suspected findings. We work to provide temporary solutions until permanent repairs can be made when we find leaks hiding behind insulation.

Leaks behind insulation can cost you money, staying out of sight for a long length of time without you knowing. Getting behind the insulation and tackling everything improves plant performance for better peace of mind and cost savings.

Preventative Maintenance for Your Condenser Steam Inlet Expansion Joint

Recurring inspections for your condenser steam inlet expansion joint allow plant personnel to conduct trend analyses. This can greatly help you make informed decisions about the condition of the material and is far less costly over time to be proactive.

Only waiting to react to a catastrophic failure vs being proactive with scheduled maintenance can greatly impact costs. Always err on the side of avoiding an unexpected shutdown that could lead to unforeseen economic impacts. Regular maintenance helps prevent those costly shutdowns while giving you critical data about the performance of your condenser steam inlet expansion joint.

Bundled Services from One Team

AES makes plant maintenance easy with one vendor for all you need. This reduces safety hazards, downtime, miscommunications, and inefficiencies. Our crews have a thorough understanding of plant safety and operating procedures. Everyone is cross-trained and equipped with the knowledge to handle every job.

No matter the work, get the same quality of workmanship from start to finish. We are safely providing services and products to optimize operational efficiency because AES is The Efficiency Expert.

Our Dedication to Quality and Safety

The best skills and solutions don’t mean anything without safety and quality. We offer the quality promise, always taking the time to educate and encourage our personnel to speak up, both for quality and for safety. This improves plant performance, reduces downtime, and ensures everything operates smoothly.

We offer video-based training, third-party classes, on-the-job instruction for hands-on skills, and regularly ask our crews to demonstrate their knowledge of the equipment, products, and services. Leaders at AES demonstrate the values of safety, quality, and teamwork.

Plus, we inspect, test, and upgrade our equipment on a regular basis. Our customers can rest assured that we will always send a top-notch crew and equipment to ensure every project is completed to your satisfaction.

Get in Touch with AES Today

See exactly why we’re called the Efficiency Experts. AES crews do not shy away from insulation, inleakage, or any other plant maintenance. With a safety-first attitude and a dedication to teamwork and communication, our crews are equipped with the knowledge and skills to handle whatever your plant needs.

Call us today to learn more about our services for plant operations. Whether it’s tube leaks or multiple services, we can help improve the efficiency of your plant. And the cost savings alone will be worth talking about.

See the difference, call today.

American Efficiency Services

American Efficiency Services was founded in 2001 to provide quality, satisfaction-guaranteed helium leak detection services to the power generation marketplace. AES has grown in sales, staff, and scope each year since its founding and now has offices in Maryland, Missouri, Florida, and Texas to serve customers across the nation – and the world – 24 hours a day/7 days a week.

- American Efficiency Services