Leak Detection: What to Know About Plant Maintenance

Do you know how much condenser air inleakage is costing you? What about condenser tube leaks? If not found, leaks can cost you thousands of dollars and lower overall efficiency of operations.

Stop the leaks, save the money, and run better: what to know about leak detection for power plants and industrial markets.

With a reputation as the efficiency experts, American Efficiency Services knows where to look for common leaks, where unusual leaks may be hiding, and how to handle tube leaks for correction and better operation.

Learn more about where your leaks are hiding and how AES can improve efficiency for you.

Table of Contents

Some of the Most Common Sources of Identified Leaks

The most important part of finding leaks is knowing where the most common leaks come from. Before spending resources on finding hard-to-find leaks, you want to identify and check the most common sources first. This can lead to quicker findings, faster resolutions, and improved efficiency in less time.

With years of experience and extensive knowledge, AES has become the experts when it comes to finding leaks and knowing exactly where to look first.

- Condenser expansion joints (steam inlet system)

- Turbine shaft seals / shaft seal housings

- Under insulation leaks

- Hotwell drain

- Condensate pump expansion joints

- Condensate pump shaft seals

- Rupture Disc

- Leaking valve packings on closed valves

- Incomplete repairs during outages

- Valves that are supposed to be closed

Air Inleakage Lurking in Unusual Areas

Air inleakage can be tricky. The unintentional entry of air into the closed system can greatly disrupt efficiency and overall operations. And you may not even know it’s happening!

Your crew should know where to look for common leaks and where to look for uncommon leaks, too. A plant inspection can help find air inleakage that is lurking out of sight, in casings and shells, and even by drains. Having the right equipment and team to find air inleakage can dramatically improve plant operations and increase your efficiency.

Some of the most unusual areas where we’ve found leaks include:

- Gland Steam Exhauster Loop Seal Drain

- Turbine Casing (Shell) Leaks

- Condenser Bearing Seal (Slop) Drain

- Welds at the Base of Condenser

- High Pressure Turbine Seals

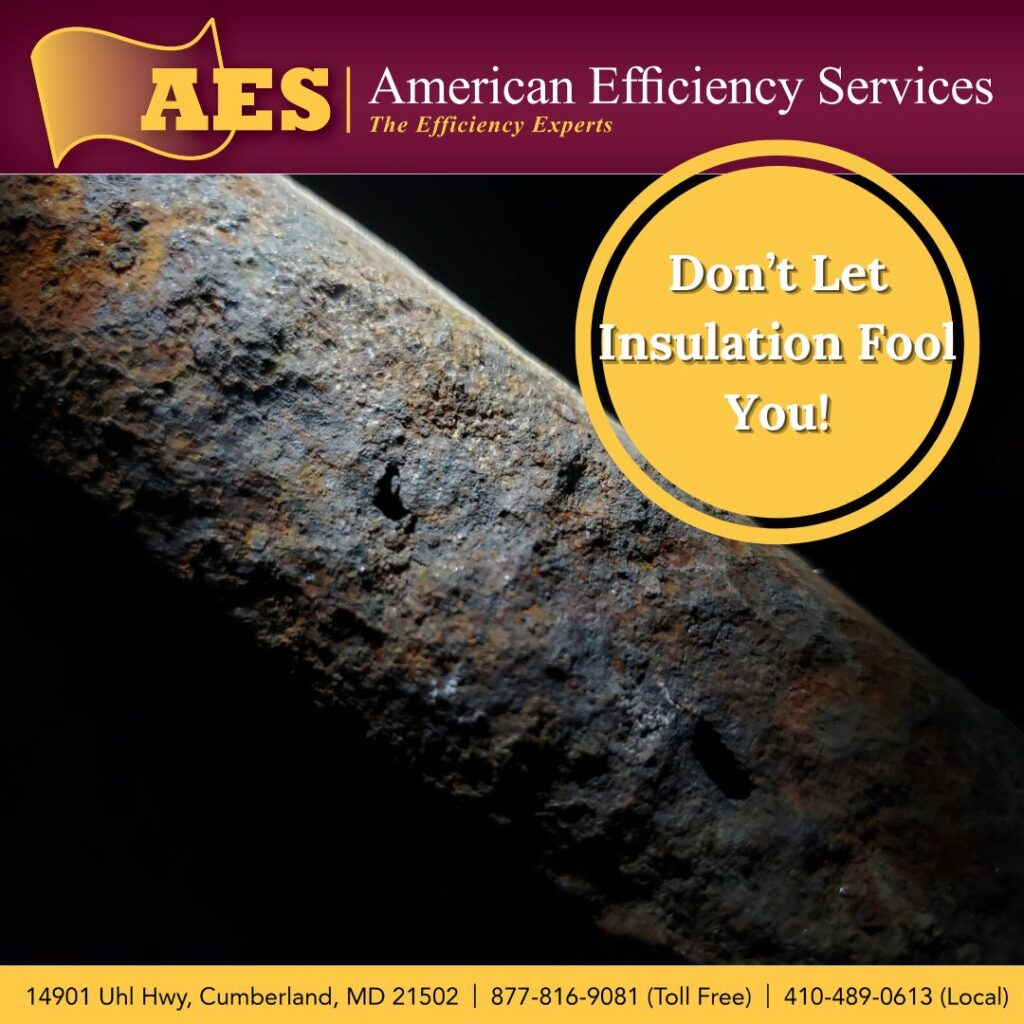

Don’t Let Insulation Fool You!

Sometimes the hardest leaks to find are the ones right under your nose. Have you been checking the insulation? Insulation is no match for our crews!

You may not want to pull back the insulation or see what’s hiding underneath, but it’s the only way for AES to confirm our findings and provide a temporary solution until permanent repairs can be made. We work with you to protect plant operations, both with a temporary solution and permanent repairs.

While insulation may be a pain, it’s a bigger risk to let operation efficiency dip down and risk losing thousands of dollars without knowing it. With AES, we work fast, report all of our findings, and complete tailored solutions.

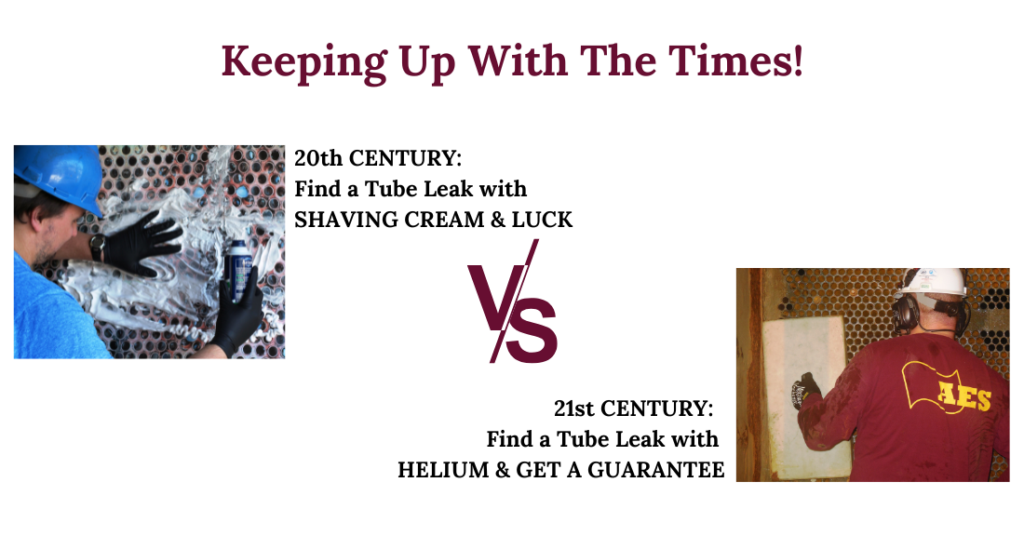

Tube Leaks Through the Ages

20th CENTURY: Find a Tube Leak with SHAVING CREAM & LUCK

21st CENTURY: Find a Tube Leak with HELIUM & GET A GUARANTEE

At AES, we use advanced helium leak detection technology to locate condenser tube leaks. Our experienced leak detection teams work to eliminate condensate contamination and improve performance to get your plant operating at full power.

We’ve moved away from old tricks like shaving cream and now have proven methods that give you a guarantee. Helium leak detection helps us find leaks quickly, plug the leaks, and give you a complete report of all findings and repairs.

Do You Know Where Your Leaks are Located? AES Can Help

American Efficiency Services has you covered if you’re dealing with a tube leak. We specialize in identifying single or multiple tube leaks efficiently. Once located, our team will plug the leaks, perform a retest, and restore your unit’s chemistry to normal. Count on us to keep your system running smoothly!

Plus, let AES conduct an inspection audit to identify your leak(s), make repair recommendations, and get your unit back to optimal efficiency. We handle leak detection, repairs, condenser inleakage, and more.

Don’t forget to inquire about our Expansion Joint, Eddy Current, Tube Cleaning, and Retubing services! With one crew, you can get it all done with expert service and expedited efficiency.

Frequently Asked Questions

What are the most common sources of leaks in power plants and industrial systems?

Common leak sources include condenser expansion joints, turbine shaft seals, under insulation, hotwell drains, condensate pump seals, rupture discs, leaking valve packings, incomplete repairs, and improperly closed valves.

Why is air inleakage a concern for plant operations?

Air inleakage disrupts efficiency and operations by allowing unwanted air into closed systems. These leaks can be hard to detect but significantly lower performance until repaired.

How does AES detect leaks hidden under insulation?

AES inspects beneath insulation to confirm leaks, providing temporary solutions to keep operations running until permanent repairs can be made.

What method does AES use to detect condenser tube leaks today?

AES uses advanced helium leak detection, a precise and guaranteed method that replaces outdated practices like shaving cream tests.

How can AES help restore plant efficiency after detecting leaks?

AES locates and plugs leaks, performs retests, restores chemistry to normal, and provides inspection audits with tailored repair recommendations to improve overall efficiency.

American Efficiency Services

American Efficiency Services was founded in 2001 to provide quality, satisfaction-guaranteed helium leak detection services to the power generation marketplace. AES has grown in sales, staff, and scope each year since its founding and now has offices in Maryland, Missouri, Florida, and Texas to serve customers across the nation – and the world – 24 hours a day/7 days a week.

- American Efficiency Services