AES’ Approach to Tube Cleanings to Improve Efficiency

When American Efficiency Services visits a facility to clean tubes, our crews don’t just make the inside of the tubes like new – we make sure the whole condenser looks like new. Our comprehensive approach is designed to optimize efficiency for the plant. By approaching the condenser as a whole, we are more likely to improve performance, locate unidentified leaks or other issues, and complete a thorough cleaning that lasts.

When it comes to AES, our crews make sure to leave their workstations better than the way they found them, and that includes the jobsite as a whole. Dive in to see the before and after tube cleaning difference, how we approach chemical cleanings, and the cost savings benefits from regularly scheduled cleanings.

Table of Contents

AES Descales ALL Kinds of Tubes Safely and Efficiently

Descaling condenser and heat exchanger tubes takes intensive planning to achieve safety and operational success. Prior to any project, especially chemical cleaning, AES guarantees that each system and proposed setup procedure undergoes a safety evaluation. It’s just one part of our comprehensive safety plan that we bring to every job.

A few of the items that we review include:

- Product selection

- Product interaction with humans and equipment

- Work area

- System redundancies (to protect from any type of equipment failure)

- How to properly transport the spent product from the work area safely

As the saying goes, “you are only as strong as your weakest link,” so we review every link equally. Below are just some of the types of tubes AES has descaled:

• Chiller Tubes

• Plate & Frame

• Boiler Tubes

• All Types of Heat Exchangers

• Other Water-Cooled or Heated Equipment

What Substances Are Used to Chemically Clean Tubes?

The heat exchanger descaling chemical process utilizes safe, yet powerful, acids to quickly dissolve deposits. At AES, we exclusively use the ScaleBreak® line from Goodway Technologies as part of our chemical cleaning. They work without the high corrosion rates associated with simple acids.

ScaleBreak® is safe for use on a wide variety of metals, plastics, and rubber and quickly helps improve operating efficiency. Plus, it can help extend the life of your equipment. The advanced formulas are fortified with powerful low foaming wetting and penetrating agents and superior corrosion inhibitors.

Heat Exchanger Cleaning: AWT-100X Solutions

Why do we use the AWT-100X Solutions? Many different types of cleaning heads can be fitted to the AWT-100X shaft, to handle whatever deposits are encountered during heat exchanger cleaning and maintenance.

These cleaning heads range:

- Nylon brush for light deposits

- Stainless-steel wire buffing tool for light to medium deposits

- PCH-180 abrasive cleaning head

- Carbide drill tip (when the tubes are heavily plugged with debris)

Depending on the deposit, several passes of various cleaner heads may be required to return the tube to its maximum efficiency. Whatever the deposit, AES will identify a program that will clean your tubes – call today and discover the difference.

Why is Mechanical Tube Cleaning Preferred Over Hydroblasting?

COST EFFICIENT AND ECO-FRIENDLY!! Smaller crew sizes and shorter cleaning times result in less down time and cost savings. Reduced water usage conserves water.

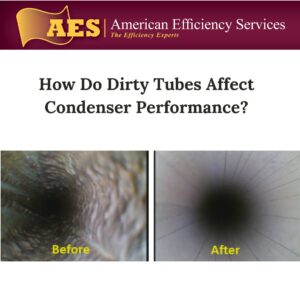

How Do Dirty Tubes Affect Condenser Performance?

- Dirty tubes reduce heat transfer

- Reduced heat transfer lessens efficient cooling

- Less efficient cooling results in increased back pressure

- Increased back pressure will lead to poor condenser performance

- Poor condenser performance means increased costs

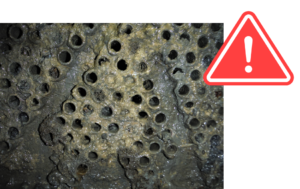

If your condenser or heat exchanger tubes look like this

On the Job

Job Highlight from AES

AES tube cleaning crews go above and beyond to ensure safety and operational integrity. During an outage at a Southern US facility, we cleaned four tube bundles with stainless steel brushes using water pumps.

The scope of work included cleaning every tube, taking before and after tube internal boroscopes images, collecting a deposit sample for further analysis, plotting plugged tubes on the tube bundle diagram, and providing a detailed final report to the customer.

AES crews are committed to leaving the tubes and work area cleaner than when we arrived and throughout the shift, and every evening prior to leaving, all mud and debris generated from the day’s work is cleaned up. Never worry when AES is on the job.

Schedule Today – Request Your Quote

One company, total efficiency services. American Efficiency Services is available across the US and worldwide. Contact us to see if we’re a good fit for your next tube cleaning. Get a quote, a breakdown of our approach, and any recommended services to help restore operations.

Frequently Asked Questions

What makes AES’ tube cleaning approach different from others?

AES cleans not only the inside of the tubes but also ensures the entire condenser looks like new. This whole-system approach improves plant efficiency, detects hidden leaks, and results in longer-lasting cleanings.

What types of tubes can AES descale?

AES safely and efficiently descales chiller tubes, boiler tubes, plate & frame, all types of heat exchangers, and other water-cooled or heated equipment.

What chemical does AES use for descaling, and why?

AES uses the ScaleBreak® line from Goodway Technologies because it dissolves deposits quickly without the high corrosion rates of typical acids. It’s safe for metals, plastics, and rubber and includes corrosion inhibitors and penetrating agents.

Why is mechanical tube cleaning preferred over hydroblasting?

Mechanical cleaning is safer, reduces injury risk and equipment damage, uses less water, requires smaller crews, shortens downtime, and cuts overall costs.

How do dirty tubes affect condenser performance?

Dirty tubes reduce heat transfer, which lowers cooling efficiency, increases back pressure, harms condenser performance, and ultimately raises operating costs.

American Efficiency Services

American Efficiency Services was founded in 2001 to provide quality, satisfaction-guaranteed helium leak detection services to the power generation marketplace. AES has grown in sales, staff, and scope each year since its founding and now has offices in Maryland, Missouri, Florida, and Texas to serve customers across the nation – and the world – 24 hours a day/7 days a week.

- American Efficiency Services